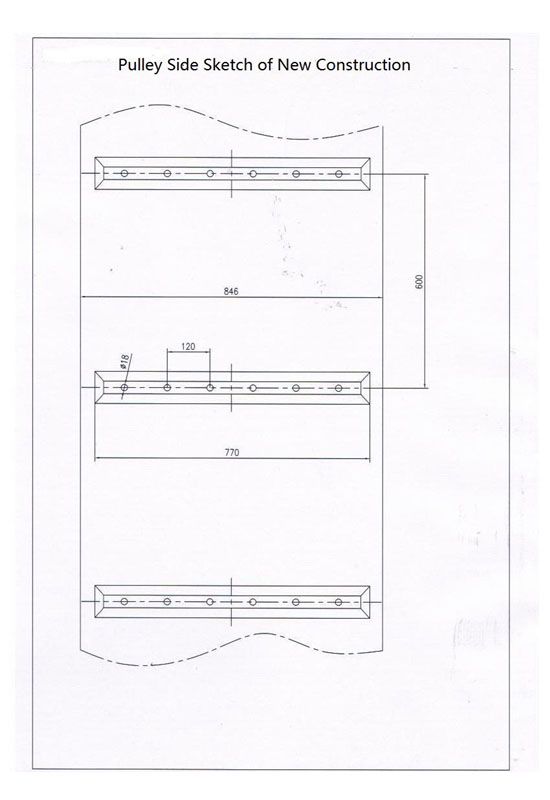

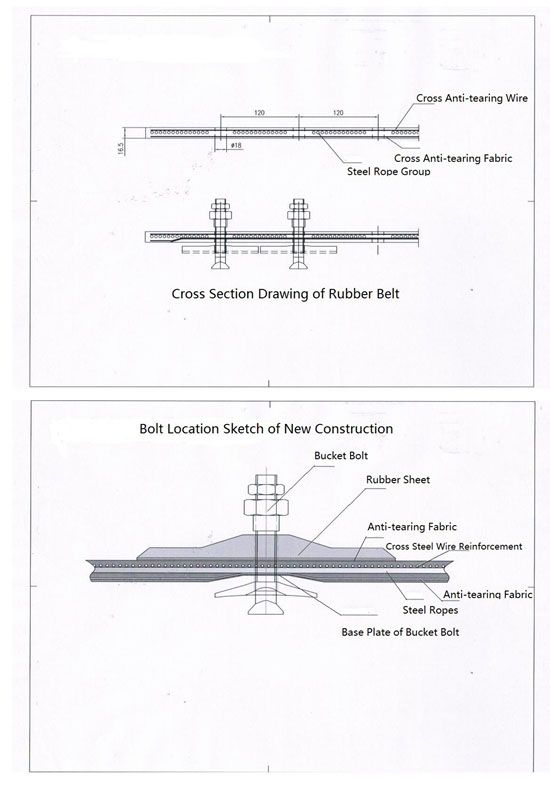

Front special high intensity steel wire belt is completely different with traditional belt at the belt thickness, steel wire density, warp and woof layout and steel wire thickness ect. Such belt composing the steel skeleton both in longitudinal and transeverse ensure the safety of connectivity and load balanced distribution of the bucket. The using effect show that such special steel wire belt completely satisfied the requirement of mass transportation volume and ultrahigh heave.

Front special high intensity steel wire belt is completely different with traditional belt at the belt thickness, steel wire density, warp and woof layout and steel wire thickness ect. Such belt composing the steel skeleton both in longitudinal and transeverse ensure the safety of connectivity and load balanced distribution of the bucket. The using effect show that such special steel wire belt completely satisfied the requirement of mass transportation volume and ultrahigh heave.

Recent years, Design lnstitute scientific researcher strived to make technological breakthrough, improved the formula, material and processing technic. The new developed steel wire belt have a higher moment temperature resistance which can reach to 180℃, and make N—TGD elevator apply to high temperature pulverized material conveying, like slag, cement of discharge from mill, cement of come into silocand fly ash ect delivery.

Table of conveying capacities

| Bucket width(mm) | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | |

| Bucket volume(L) | 5 | 6.5 | 14.6 | 18 | 29 | 37 | 58 | 73 | 99 | 114 | |

| Conveying Capacitym³/H | Φ100% | 85 | 117 | 225 | 280 | 450 | 570 | 950 | 1255 | 1547 | 1780 |

| Φ75% | 63 | 88 | 168 | 210 | 338 | 428 | 712 | 941 | 1160 | 1335 | |

| Lifting height(m) | >100 | >100 | >100 | >120 | >120 | >120 | >130 | >130 | >130 | >130 | |

Notes:

①The bucket volume is the volume when taking water,Φ is the material filling ratio.

②The maximum lifting height is the center distance C between the head shaft and the tail shaff.

This construction of rubber belt was patented to Front Industry in China. Our patent No.:201220159603

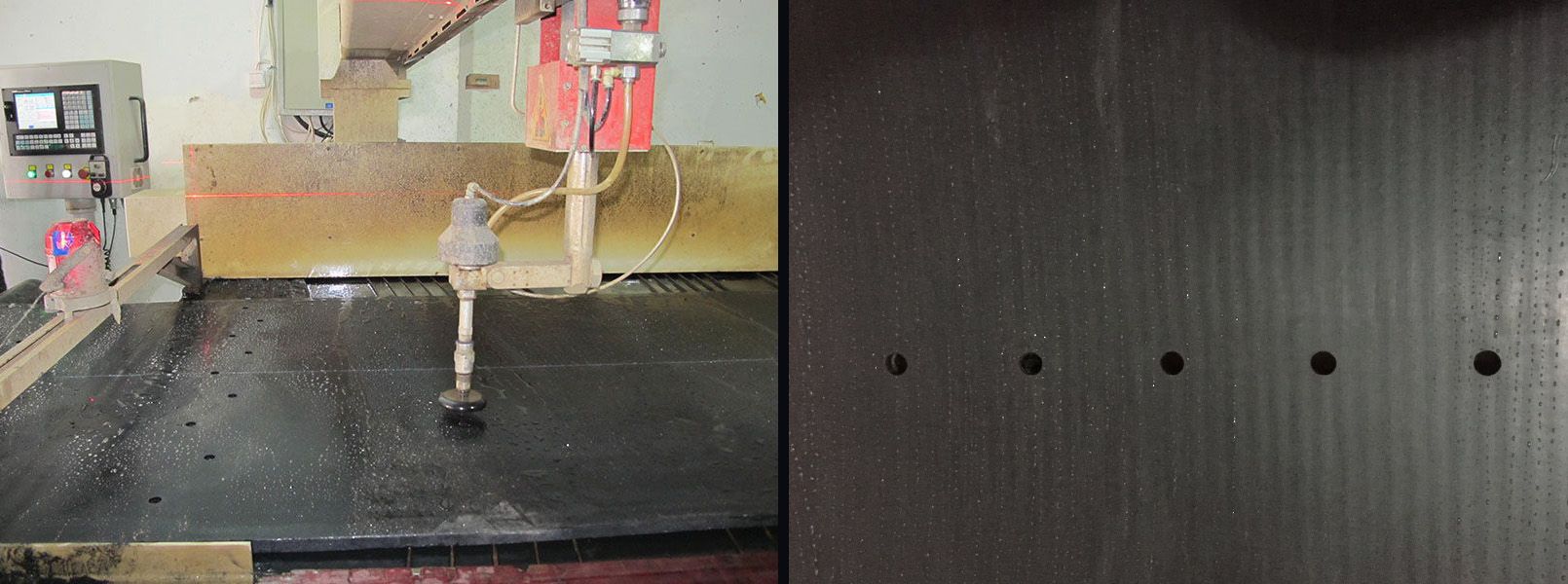

The perfect combination of water jet cutting technology

Programed control system with screen operation interface

Regular configuration matched with computer data inputting

Precise holes diameter with+/-0.3mm tolerance

The space of holes and rowed holes 100% in conformance with the drawing

Cold drilling,rubber performance secured

Perfect belt appearance,satisfied delivery to the customers

Suitable for conveying material vertically, widely used in buiding. Miniing. Chemical. Light industry, power station and grain ect, field.

Please fill out the form below and we will get back to you as soon as possible.